- Flex PCB Blog

- PCB Assembly Blog

- FPC Research Blog

- Preparation of FPC based on ultrasonic spraying method_4_Experimental Results

- Preparation of FPC based on ultrasonic spraying method_3_Experimental Procedure

- Preparation of FPC based on ultrasonic spraying method_2_Experimental Platform and Principle

- Preparation of FPC based on ultrasonic spraying method_1_abstract

- Research on Layout Design Method of Ultra-thin FPC_4_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_3_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_2_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_1_introduction

- Research progress on polyimide FPC_2_the field of FPC

- Research progress on polyimide FPC_1_Introduction

- Analysis of Vibration Characteristics of FPCBs _4_Summary

- Analysis of Vibration Characteristics of FPCBs _3_Finite Element Analysis

- Analysis of Vibration Characteristics of FPCBs _2_Theory of Vibration Analysis

- Analysis of Vibration Characteristics of FPCBs Under Random Vibration_1_Introduction

- Design Methods for FPCBs_5_Practical Application

- Design Methods for FPCBs_4_Electrical Circuit Design and Examples

- Design Methods for FPCBs_3_Structure Design Method and Examples

- Design Methods for FPCBs_2_Component Selection Methodology and Examples.

- Research on Design Methods for FPCBs

- Application of MPW technique for FPCBs _4_Summary

- Application of MPW technique for FPCBs_3_Experimental results

- Application of MPW technique for FPCBs_2_Experimental setup

- Application of MPW technique for FPCBs_1_Principle of MPW

- Application of FPCB in PC motherboards_4_ Results and discussion

- Application of FPCB in PC motherboards_3_ Numerical analysis

- Application of FPCB in PC_2_ Experimentation

- Application of FPCB in PC motherboards

- A Bus Planning Algorithm for FPC Design _4_Experimental result

- A Bus Planning Algorithm for FPC Design _3_Proposed Algorithm

- A Bus Planning Algorithm for FPC Design _2_Preliminaries

- A Bus Planning Algorithm for FPC Design _1_Introduction

Research progress on polyimide FPC_2_The field of FPC

2.The field of flexible printed circuit boards (FPC)

2.1 FPC

Flexible Printed Circuit Boards (FPC) are products that consist of a polyimide film substrate coated with an adhesive, followed by the application of copper foil to form copper circuits. Here is a brief overview of the representative FPC manufacturing process: First, an epoxy resin or other adhesive is applied to the polyimide film. After drying, it is temporarily bonded to the copper foil using a pair of hot rollers. The adhesive is then fully cured to obtain the Copper Clad Laminate (CCL), also known as FCCL. A photoresist is applied to this composite board to outline the desired circuitry. Under acidic conditions, the copper is etched away (etching plate), and the photoresist is removed, leaving behind the copper circuit substrate. Typically, a polyimide film with an adhesive layer, known as a coverlay, is laminated onto this substrate using a press, thus completing the sandwich structure of the FPC. Figure 1 illustrates a schematic diagram of the FPC.

Figure 1 Cross-sectional view of a Flexible Printed Circuit Board (FPC)

Apart from polyimide films, polyester (PET) films can also be used as substrate films. In the past, FPCs were only used as electrical connection materials. However, recent advancements in IC (Integrated Circuit) mounting technology, combined with high integration and density, are accelerating the high-functionalization of FPCs. With this development, the use of polyimide films with excellent heat resistance, specifically those with solder bath resistance, has been rapidly increasing in this field. In 2000, the domestic sales volume of polyimide films in Japan reached 1,150 tons, of which 65% was used for FPCs. It is predicted that FPC sales will grow at an annual rate of 10% in the future. Additionally, it is reported that Japan's production bases will shift from Japan to mainland China.

2.2 Types of FPC (FCCL)

FPC using polyimide films can be classified as follows:

- Three-layer structure substrate made by coating a general-purpose adhesive such as epoxy resin on a polyimide film and then laminating it with copper foil (the manufacturing process introduced earlier)

- Pseudo two-layer structure substrate using a thermoplastic polyimide as the adhesive

- Adhesive-free two-layer structure substrate formed by depositing thin layers on a polyimide film through evaporation, sputtering, etc.

- Adhesive-free two-layer structure substrate made by coating a polyimide or its precursor, polyamic acid solution, on copper foil and then curing it.

2.3 Technical Trends in FPC

As mentioned earlier in section 1), until about 10 years ago, FPCs were primarily used as simple electrical wiring materials, and three-layer substrates with general-purpose adhesives were used in applications such as cameras and printers. However, in recent years, the requirements for high functionality, miniaturization of FPC wiring, and IC mounting technology have become more demanding, necessitating high electrical reliability, heat resistance, and dimensional stability. Market demands have evolved beyond the capabilities of the original general-purpose three-layer substrates. Consequently, the focus has recently shifted to the types described in sections 2), 3), and 4) above.

2.4 Polyimide Films Used in FPC

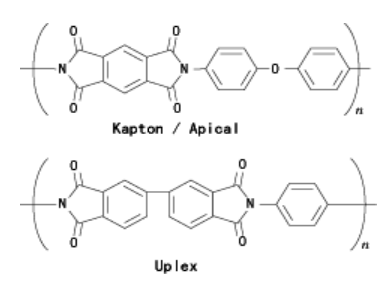

In the aforementioned types 1), 2), and 3) of FPCs, industrially produced polyimide films are used as the substrate films. Examples include Dupont's Kapton, Kaneka Chemical's Apical, and Ube Industries' Uplex. Each company is developing complementary products to meet market demands and applications, manufacturing, selling, and distributing polyimide films with various chemical structures. The chemical structure of a representative general-purpose variety is as follows:

Traditionally, general-purpose polyimide films were most commonly used in FPCs. However, in recent years, to achieve finer wiring, there has been a growing demand for FPC manufacturing processes or prepared FPCs with minimal dimensional changes. To meet these market requirements, compared to general-purpose types, it is recognized that new polyimide films should possess the following characteristics:

- Low moisture absorption expansion coefficient

- Low coefficient of thermal expansion or similar to that of copper foil

- High modulus

Figure 2 Chemical Structure of Representative Polyimide Films

2.5 Polyimide Adhesives

In the FPC example mentioned in section 2.2, various types of polyimide adhesives have been successfully developed for use as adhesives, with linear thermoplastic polyimides being the mainstream. For FPC applications, the glass transition temperature (Tg) generally needs to be controlled within the range of approximately 150-250°C, which becomes a key point in molecular design. To achieve this, aromatic rings are primarily used in the main chain, but attempts have been made to introduce functional groups such as meta-long-chain ethers, carbonyls, and siloxanes. The introduction of aliphatic groups like ethylene is relatively easy to control Tg, but it has the disadvantage of poor short-term heat resistance.

The demand for FPCs using polyimide adhesives is expected to grow significantly in the future. However, currently, they still require high temperature and pressure to laminate with copper foil, making processability improvement a major issue. Maintaining a balance between Tg control and heat resistance while improving processability is a subject of intense competition among major companies.

2.6 Cast Coated Polyimide

The FCCL type 4) mentioned in section 2.2 is a completely different manufacturing method from the 1)-3) types described earlier, which use polyimide films as substrates. This method involves coating a polyimide resin or its precursor, polyamic acid solution, on copper foil, followed by drying to form a polyimide film on the copper foil. As an example of this type of FCCL, Nitto Denko Corporation has successfully developed a product. It is produced by coating a unique polyimide resin on copper foil using a special manufacturing method, followed by drying and curing.