- Flex PCB Blog

- PCB Assembly Blog

- FPC Research Blog

- Preparation of FPC based on ultrasonic spraying method_4_Experimental Results

- Preparation of FPC based on ultrasonic spraying method_3_Experimental Procedure

- Preparation of FPC based on ultrasonic spraying method_2_Experimental Platform and Principle

- Preparation of FPC based on ultrasonic spraying method_1_abstract

- Research on Layout Design Method of Ultra-thin FPC_4_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_3_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_2_Analysis of Layout Design Methods

- Research on Layout Design Method of Ultra-thin FPC_1_introduction

- Research progress on polyimide FPC_2_the field of FPC

- Research progress on polyimide FPC_1_Introduction

- Analysis of Vibration Characteristics of FPCBs _4_Summary

- Analysis of Vibration Characteristics of FPCBs _3_Finite Element Analysis

- Analysis of Vibration Characteristics of FPCBs _2_Theory of Vibration Analysis

- Analysis of Vibration Characteristics of FPCBs Under Random Vibration_1_Introduction

- Design Methods for FPCBs_5_Practical Application

- Design Methods for FPCBs_4_Electrical Circuit Design and Examples

- Design Methods for FPCBs_3_Structure Design Method and Examples

- Design Methods for FPCBs_2_Component Selection Methodology and Examples.

- Research on Design Methods for FPCBs

- Application of MPW technique for FPCBs _4_Summary

- Application of MPW technique for FPCBs_3_Experimental results

- Application of MPW technique for FPCBs_2_Experimental setup

- Application of MPW technique for FPCBs_1_Principle of MPW

- Application of FPCB in PC motherboards_4_ Results and discussion

- Application of FPCB in PC motherboards_3_ Numerical analysis

- Application of FPCB in PC_2_ Experimentation

- Application of FPCB in PC motherboards

- A Bus Planning Algorithm for FPC Design _4_Experimental result

- A Bus Planning Algorithm for FPC Design _3_Proposed Algorithm

- A Bus Planning Algorithm for FPC Design _2_Preliminaries

- A Bus Planning Algorithm for FPC Design _1_Introduction

Application of flexible printed circuit board (FPCB) in personal computer motherboards

Focusing on mechanical performance_1_introduction

Abstract

Flexible printed circuit boards (FPCBs) are being used extensively in current electronics devices because of their excellent flexibility, lightweight, and reduced thickness. In the present study, a proposed novel approach that utilizes FPCB as a substrate for motherboards is investigated. Deflection and stress are the key factors that determine the feasibility of FPCB motherboards. As flow velocity increases, flow-induced deflection and stress also become more prominent. The present study also explores several configurations of the motherboard, such as different fastening options and component layouts. This fluid–structure interaction (FSI) study is performed using the fluid solver FLUENT and the structural solver ABAQUS, coupled online using the Mesh-based Parallel Code Coupling Interface (MpCCI). A simple experiment was also conducted to substantiate the FSI simulation technique utilized in the present study.Although the present study on FPCB primarily focuses on the motherboard, the findings could also provide information for other FPCB applications.

1. Introduction

Flexible printed circuit boards (FPCBS) can be used as alterna- tives to rigid printed circuit board (PCB) in certain applications because of its excellent flexibility, twistability,and light weight.FPCB facilitates a space-efficient system design, reduces size and weight, improves the internal appearance of a system, and offers low-cost installation. Over the years,FPCBs have been widely used in numerous electronic devices,but their application as personal computer(PC) motherboards is still rare. Compared with rigid PCB, FPCB permits much higher deflection in operations, especially under flow conditions in typical PC systems. Therefore, durability and long-term performance are the primary concerns in the use of FPCB as motherboards. Numerous studies have focused on this area, and a review of previous research, which builds the back- ground for the current study, is presented.

Azar and Russell experimentally studied the effect of component layout and geometry on flow distribution in a circuit pack. They found that the flow in electronic enclosures was highly three dimensional, and the location and orientation of components with large aspect ratio can significantly affect flow distribution. A similar study was reported by Lee and Mahalingam, who used a computational fluid dynamics (CFD) tool to evaluate the velocity and temperature fields of air flow in a computer system enclosure and correlated the predictions with real-time experiments.

Dealing with component-PCB heat transfer, Rodgers et al. performed numerical and experimental analyses to assess the predictive accuracy of the CFD tool for the thermal analysis of electronic systems in natural- and forced-convection modes. A detailed characterization of the air-flow patterns around PCB-mounted elec- tronic components using few complimentary flow visualization techniques was also reported.

A numerical solution for the steady-state forced convection of air flowing through a horizontally oriented PCB assembly under laminar flow conditions was developed by Leung et al. Shank- aran et al. [8] proposed the ‘‘zoom-in modeling, a multi-level approach with an exact boundary condition import, for accurate and time-efficient CFD design calculations for a populated system cooled by forced air flow. Leon et al. used the FLUENT code to obtain the optimal layout for cooling fins in forced-convection cooling by uniquely considering both the heat flux and flow resis- tance. A model of forced-convection cooling was also reported by Baelmans etal. who observed that fan-induced swirling flows were difficult to predict with standard k–ε turbulence models. In addition, Cole et al. investigated the aerodynamic and thermal interactions of ball-grid array (BGA) packages in a real environ- ment. The effects of air flow and PCB thermal conductivity on the junction temperature were analyzed.

Extensive experiments and modeling of flow and heat transfer in axial flow fan-cooled electronic systems were conducted by Grimes et al. Experiments were conducted in fan-sucking (fan mounted at the system outlet), as well as fan-blowing (fan mounted at the system inlet), modes. The flow in the sucking mode using a laminar model was observed to be steady, uniform, and easily predictable, whereas in the blowing mode and using a turbu- lent model, the flow was unsteady, swirling, and too complex to predict with reasonable accuracy. However, heat transfer was enhanced by shifting the fan from the exhaust (sucking) to the inlet (blowing).

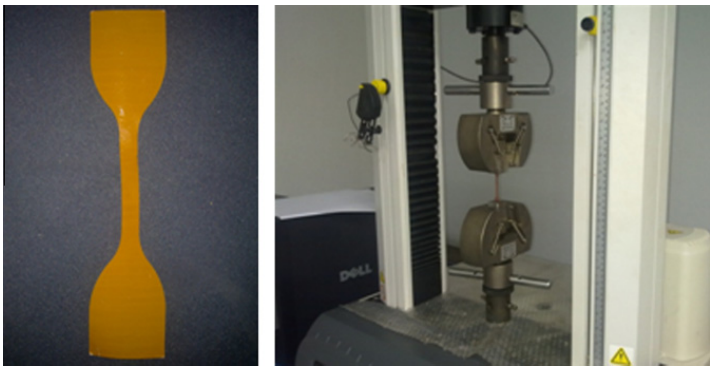

Fig.1. ASTM D638 test for PCB material.

For rigid PCB, Leicht and Skipor introduced a method of measuring the reliability of the mechanical bending fatigue of area-array packages. A global/local modeling of PCB mechanical loading was also proposed by Zhu et al. Using the finite element method (FEM) model, Shetty et al.and Shetty and Reinikainen investigated the durability of chip scale package interconnects when assembled on FR4 substrates. Lau et al. Studied plastic BGA package assemblies under a three-pointbending condition using experiments and simulations. Furthermore, Yuetal.analyzed the full-field dynamic responses of PCBs at the product level using a digital image correlation technique.

Few studies have focused on the material and structural characteristics of FPCB. Li and Jiao studied the effects of temperature and aging on the Young’s moduli of polymeric-based flexible substrates, such as polyethylene naphthalate, polyester, and poly- imide, using the Dynamic Mechanical Analyzer. Barlow et al. successfully demonstrated the feasibility and viability of FPCB for miniaturization purposes on integrated power modules. Combining FEM with optimization analysis, Ptchelintsev developed an automated procedure for the fatigue life assessment of FPCB. The fatigue behavior of thin Cu foils for FPCB was also experimentally studied by Han et al.

Considering fluid–structure interaction (FSI), Arruda and Freitas proposed a multiphysics simulation model to describe the interaction between FPCB and its surrounding air. Huang et al. investigated the mechanical reliability of a BGA mounted on FPCB under drop impact using simulation and found that stress can be reduced by increasing the height of solder joints. Interest- ingly, Siegelet al. were able to fabricate several low-cost flex-ible electronic circuits on paper substrates.

Recently, Arruda et al. have studied the flex–rigid PCB (RFPCB) interface to evaluate the cracking phenomena during thermal cycling using FEM. They found that high stresses could result in micro cracks in the connection between rigid and flex boards, and the development of stress was attributed to the design of the PCB and the non-uniformity in thermal expansion of various parts. Sun et al. [32], using FE analysis, found that some risky places exist for potential failures, such as the corners of the connecting parts of RFPCB. In addition, Das et al. discovered that the flexibility of FPCB decreased with an increasing number of metal layers. They were also able to fabricate biocompatible FPCB on a poly- dimethylsiloxane substrate.

Few studies related to PC motherboards were also conducted. Pitarresi et al. and Yating et al. addressed the FEM is- sue regarding the dynamic responses of a typical PC motherboard. They locally modeled the large components as simple blocks to avoid expensive modeling and found that the predictions corre- late well with experimental measurements. On the other hand, Darveaux et al. investigated temperature distribution on laptop computers under various conditions and observed that the operating temperature range is approximately 55–80 degrees. Tari and Yalcin suggested that placing the CPU,motherboard, and RAM on the back side of the laptop lid can passively cool the laptop.

However, to the authors’ knowledge, no literature has reported on the application of FPCB in PC motherboards. Therefore, the current work aims to study the possibility of using FPCB as moth- erboards. The present study is aimed at investigating the deflection and stress induced on the FPCB motherboard under different flow conditions. To ensure the mechanical feasibility of FPCB mother- boards, the present work uses various parameters, such as different flow velocities, fastening options, and component layouts. The fluid–structure interaction (FSI) problem is addressed using the fluid-flow solver FLUENT and structural solver ABAQUS, coupled online using the Mesh-based Parallel Code Coupling Interface (MpCCI). The flow is assumed to be three dimensional, laminar, incompressible, and unsteady. A simple experiment was also car- ried out to validate the FSI simulation technique. However, the consideration of electronic viability is beyond the focus of the pres- ent study. Although the present findings are important to FPCB motherboards in future PC development, the contributions are also significantly valuable for other FPCB applications.