- Flex PCB Blog

- Reflow Soldering PCB Temperature Curve Explanation

- What is FPC

- Special attention points for flexible circuit wiring

- Multilayer PCB Stack-up Basics | PCB Knowledge

- PCB Protection: Potting or Conformal Coating? | PCB Knowledge

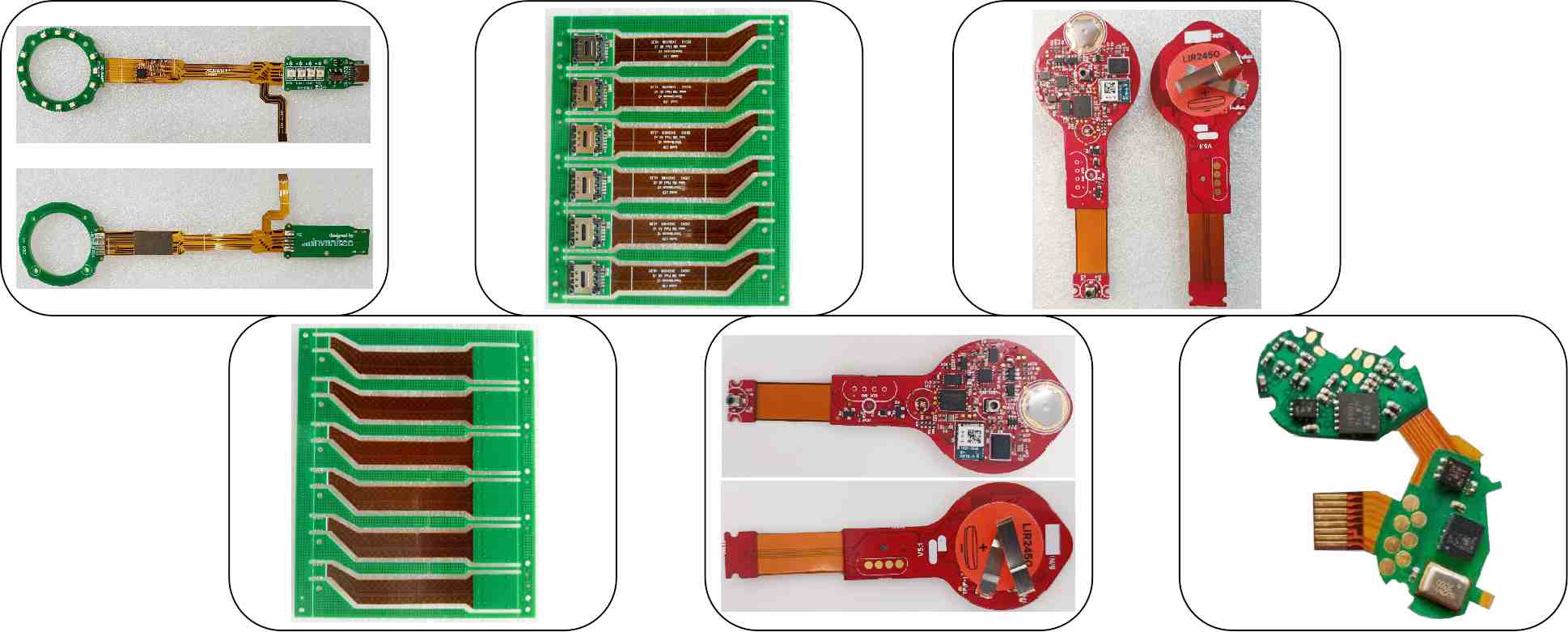

- FPCway: Specialized manufacturer of flexible printed circuit boards and rigid-flexible printed circuits

- Future Trends of Flexible Circuit Boards

- Rigid-Flex PCB Stack-up for Impedance Controlled Designs

- Control Impedance Between Rigid PCB and Flex PCB

- Flex PCB Reliability and Bendability

- Normal Flex PCB Specifications

- Flex PCB Polyimide Coverlay and Solder Mask

- Flex PCB Boards and Connectors

- About RA Copper and ED Copper

- Introduction of Flexible PCB

- 5 Tips For Designing Flexible PCB

- Advantages of FPC (Flexible PCB)

- Evolution of the Flex Printed Circuit Board

- Benefits of Using Flex Circuit Boards

- Why Rigid-Flex PCBs are Economical?

- Flexible PCB vs Rigid PCB

- Development of Flexible printed circuit board (FPC) market

- Traditional Manufacture Engineering of FPC Substrate

- Development Trend of FPC Board

- Flex PCB and the Manufacturing

- About Flex PCB design

- About Flex PCB and Assembly

- How to Ensure Flex PCB Design Success

- How to Select the Appropriate FPC Materials?

- The Differences In Rigid PCB, Flex PCB and Rigid-Flex PCB

- Flex-Rigid PCB Design Guidelines

- Beneficials for Polyimide Flex PCB Boards

- About Stiffener on Flex PCB FPC circuit Boards

- About ENIG and ENEPIG

- PCB Surface Finish Comparison

- Copper Thickness for FPC Boards

- Interconnect Solutions for Flexible Printed Circuits and Etched Foil Heaters

- Advantages and Disadvantages of Rigid-Flex PCB

- About FPC Plating Process

- About EMI shield design for Flex Printed Circuit Board

- PCB Assembly Blog

- FPC Research Blog

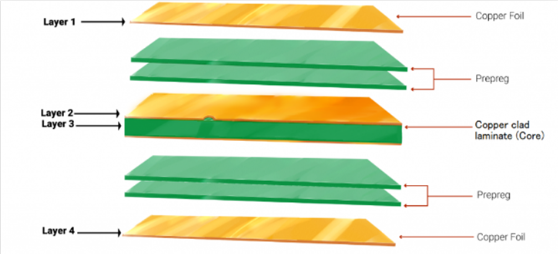

Multilayer PCB Stack-up Basics | PCB Knowledge

Single-layer PCBs and double-layer PCBs are two basic types of boards that have only one or two layers of conductive materials over the substrate. When more routing space or signal integrity is required, multi-layer PCBs are suited to meet these demands. Unlike single-layer and double-layer PCBs, multilayer PCBs stack multiple layers of conductive and insulating materials to create a complex network of connections. The stack-up typically includes copper layers, cores, substrates, and prepreg. Prepreg and core are two types of insulating materials or dielectric materials in PCBs.

Figure1 : Multilayer PCB stack-up

What is prepreg?

Prepreg, short for pre-impregnated, is a layer of fiberglass cloth impregnated with uncured epoxy resin but without any attached copper foil. In a PCB stack-up, prepreg serves as both an insulating layer and an adhesive layer. When constructing a PCB stack-up, the prepreg is placed between adjacent copper layers or between a copper layer and a core material. During the manufacturing process, high temperature and pressure cause the epoxy resin in the prepreg to flow and bond the layers together, resulting in a solid, rigid board.

Figure2 : Prepreg

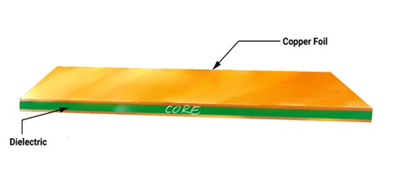

What is a core of a PCB?

The core of a PCB is the central layer of the board that provides mechanical support and rigidity. It typically consists of a laminate material made of thin layers of copper foil bonded to a rigid substrate material. The copper foil on the core can serve multiple purposes, such as providing a ground plane or a signal plane. In multilayer PCBs, there can be multiple core layers, with prepreg layers between each core layer and the outer copper layers.

Figure3 : PCB core

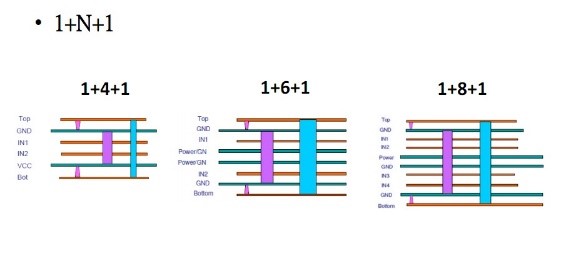

HDI Stack-up

Compared to traditional PCB stack-ups that rely on through-hole vias to interconnect layers, HDI stack-ups utilize micro-vias, blind vias, and buried vias to achieve higher routing density and better electrical performance. The X-N-X structure is a common way to describe the HDI stack-up configuration. Here, X represents the number of HDI layers with micro-vias, while N represents the number of core layers sandwiched between these HDI layers. Some common stack-up configurations include 1-N-1, 2-N-2, and 3-N-3.

To further illustrate how the X-N-X structure is applied in practice, let's consider the example of a 1-4-1 stack-up configuration. In a 1-4-1 structure, there is one HDI layer with micro-vias at the top of the PCB, followed by four core layers with no micro-vias in between, and finally another HDI layer with micro-vias at the bottom of the PCB.

Figure4:HDI Stack-up example