- Flex PCB Capability

- Flex PCB Capability

- Rigid-Flex PCB Capability

- Rigid PCB Capability

- Flex PCB Manufacture Process

- Our Flex PCB Factory

- FPC Layers Stack Up

- PCB Assembly Capability

Printed Circuit Boards are a very customized product with different copper layers and different copper tracks and different materials, etc.

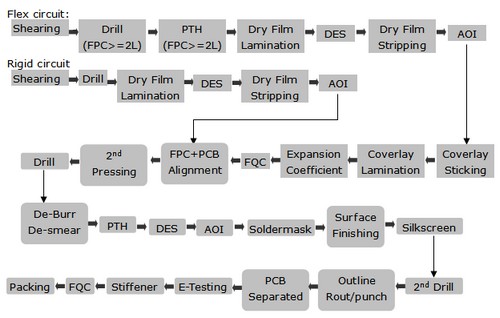

FPC has single sided FPC, double sided FPC, multi-layer FPC and Rigid-flex PCB. The main substrate is polymide FCCL and it has high heat resistance and stable size. Roughly, the process is cut the FCCL in working size, printed/exposure the copper tracks, cover the coverlay, do the surface finish, print the silkcsreen, do the stiffeners/EMI shield/PSA process, cut the required FPCs out, FQC & Shipping, etc. Below is the detailed flex PCB manufacturing process for your reference.

1. Single Sided Flexible PCB Boards Manufacturing Processes:

2. Double Sided Flexible PCB Boards Manufacturing Processes:

3. Multilayer Flexible PCB Boards Manufacturing Processes:

4. Multilayer Flex-Rigid PCB Boards Manufacturing Processes:

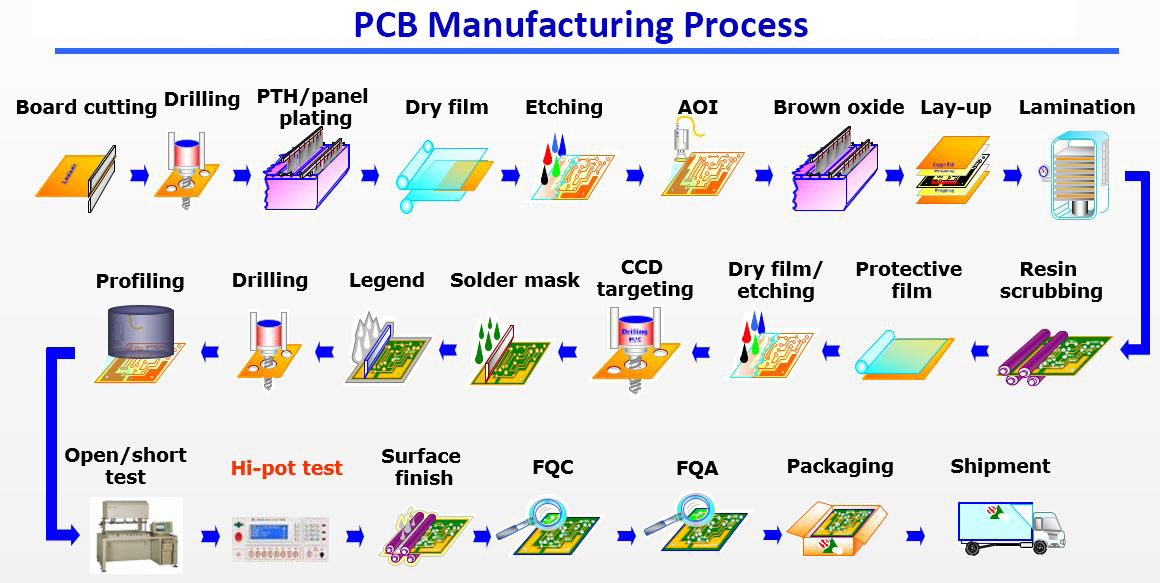

5. Multilayer Rigid PCB Boards Manufacturing Processes: