- Flex PCB Capability

- Flex PCB Capability

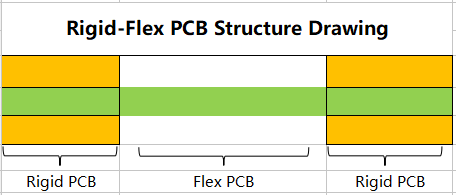

- Rigid-Flex PCB Capability

- Rigid PCB Capability

- Flex PCB Manufacture Process

- Our Flex PCB Factory

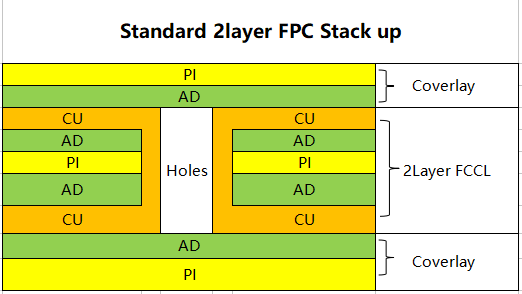

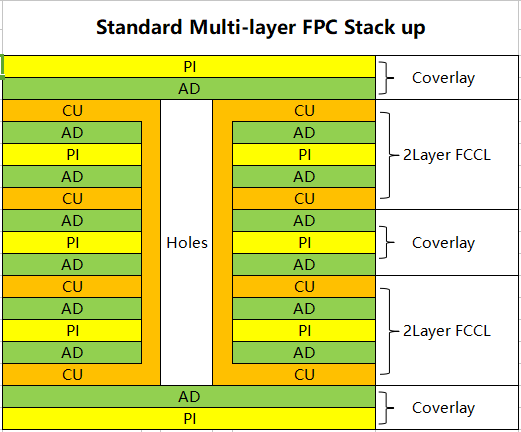

- FPC Layers Stack Up

- PCB Assembly Capability

Flexible printed circuit boards, also called Flexible PCBs or Flex PCBs or FPC Boards or just FPC. It's made by flexible insulation materials like PI, PET, etc. FPC derive their name for their flex ability to enable the circuit to be designed to fit the electronic device or product, as opposed to building the device to conform to the circuit board.

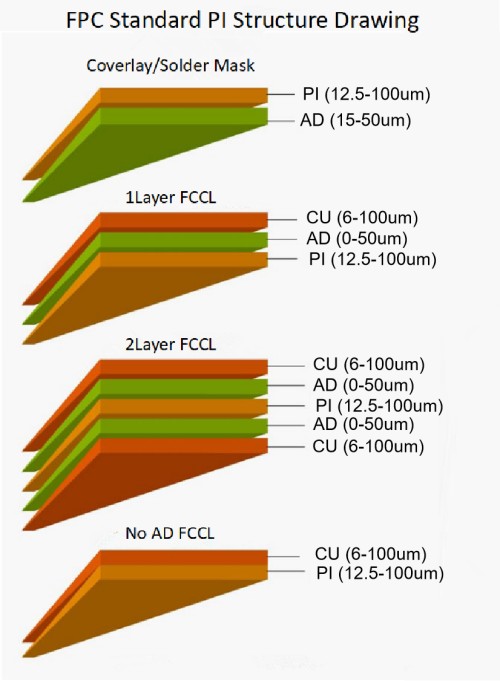

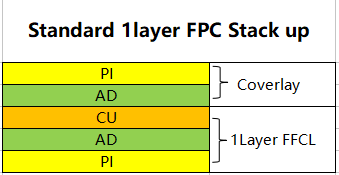

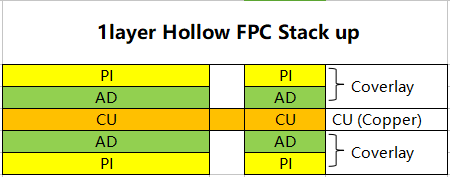

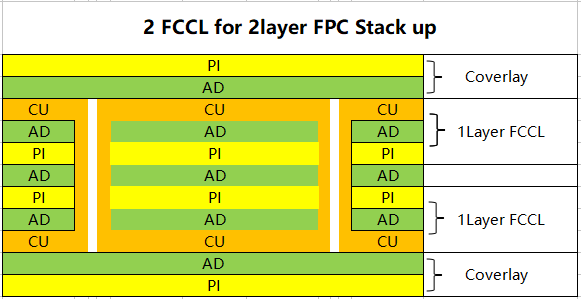

FPC has single sided FPC, double sided FPC, multi-layer FPC and Rigid-flex PCB. The main substrate is polymide FCCL and it has high heat resistance and stable size. Following are the FPC Standard PI FCCL and the stack up for Flex PCB. The FPC final thickness could be adjusted flexibly with different thicknesses of PI, adhesive, copper, etc.

| FCCL Material Thickness Detail | ||||

| Coverlay/Solder Mask | 2Layer FCCL | |||

| PI (12.5/25/50/100um, etc.) | Copper (6/9/12/18/35/70/100um, etc.) | |||

| AD (15/25/35/50um, etc.) | AD (0/12.5/20/25um, etc.) | |||

| PI (12.5/25/50/100um, etc.) | ||||

| 1Layer FCCL | AD (0/12.5/20/25um, etc.) | |||

| Copper (6/9/12/18/35/70/100um, etc.) | Copper (6/9/12/18/35/70/100um, etc.) | |||

| AD (0/12.5/20/25um, etc.) | ||||

| PI (12.5/25/50/100um, etc.) | ||||

Flex PCB Stack-up Structure | |

|  |

|  |

|  |