| Stack-up | Thickness (um) | Thickness (um) |

| Top Coverlay | 50um | |

| Copper | 18um | 18um |

| Adhesive | 13um | 13um |

| PI | 25um | 25um |

| Bottom PI Stiffener | 250um | |

| Total Thickness (um) | 100um +/-30um | 300um +/-50um |

Normally we can finish 1L & 2L Flex PCB in 5-7days, and quickest 1-2days based on the design, the production time need about 8-10days. The lead time details can be found in below form for your reference:

Lead Time for Flex PCB | ||||

| Layer | Standard FPC Specification | Quickest Protype | Standard Prototype | Production Time |

1L | 1Layer, PI, 0.05mm-0.2mm thickness, 6um-100um base copper, Yellow Coverlay, White silkscreen, ENIG | 1-2 Days | 5-7 Days | 8-10 Days |

2L | 2Layer, PI, 0.08mm-0.3mm thickness, 6um-100um base copper, Yellow Coverlay, White silkscreen, ENIG | 1-2 Days | 5-7 Days | 8-10 Days |

4L | 4Layer, PI, 0.2mm-0.4mm thickness, 6um-100um base copper, Yellow Coverlay, White silkscreen, ENIG | 3-4 Days | 8-10 Days | 10-12 Days |

6L-16L | Based on the customers requirements. | 6-8 Days | 12-14 Days | 14-18 Days |

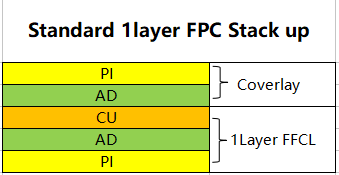

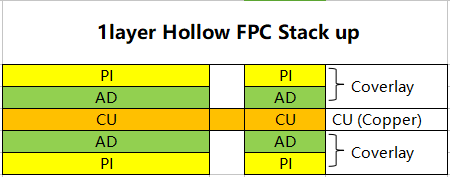

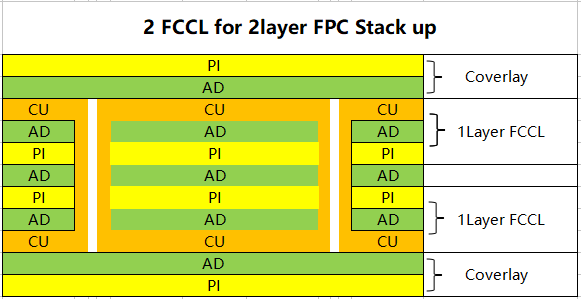

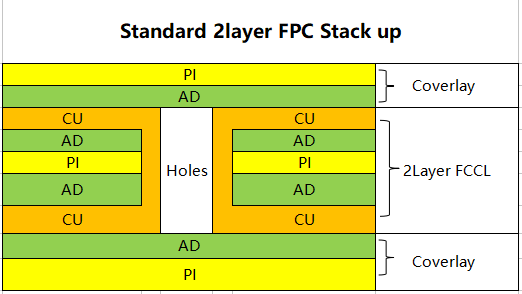

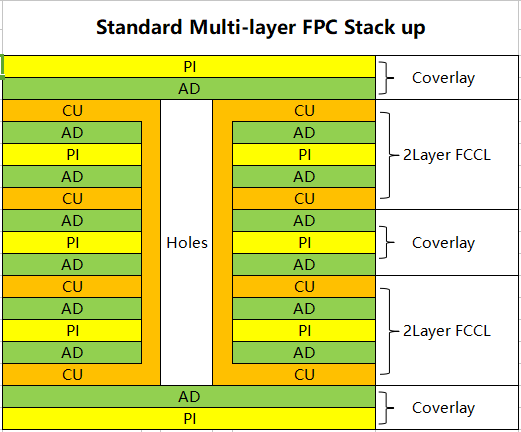

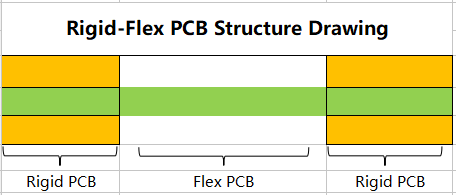

FPC has single sided FPC, double sided FPC, multi-layer FPC and Rigid-flex PCB. The main substrate is polymide FCCL and it has high heat resistance and stable size. Following are the common layer FCCL structure and stack up for Flex PCB for your reference. The FPC final thickness could be adjusted flexibly with different thicknesses of PI, adhesive, copper, etc.

| FCCL Material Thickness | ||||

| Coverlay/Solder Mask | 2Layer FCCL | |||

| PI (12.5/25/50/100um, etc.) | Copper (6/9/12/18/35/70/100um, etc.) | |||

| AD (15/25/35/50um, etc.) | AD (0/12.5/20/25um, etc.) | |||

| PI (12.5/25/50/100um, etc.) | ||||

| 1Layer FCCL | AD (0/12.5/20/25um, etc.) | |||

| Copper (6/9/12/18/35/70/100um, etc.) | Copper (6/9/12/18/35/70/100um, etc.) | |||

| AD (0/12.5/20/25um, etc.) | ||||

| PI (12.5/25/50/100um, etc.) | ||||

| Flex PCB Stack-up Structure | |

|  |

|  |

|  |