- Quick FPC Prototype

- Flex PCB Production

- Rigid-Flex PCB Prototype

- Rigid-Flex PCB Prototype | FPCway

- Flex PCB Assembly

- Rigid-Flex PCB Assembly

- Rigid PCB and Assembly

- Electronic PCBA Design

- Components Sourcing

- SMD Stencil

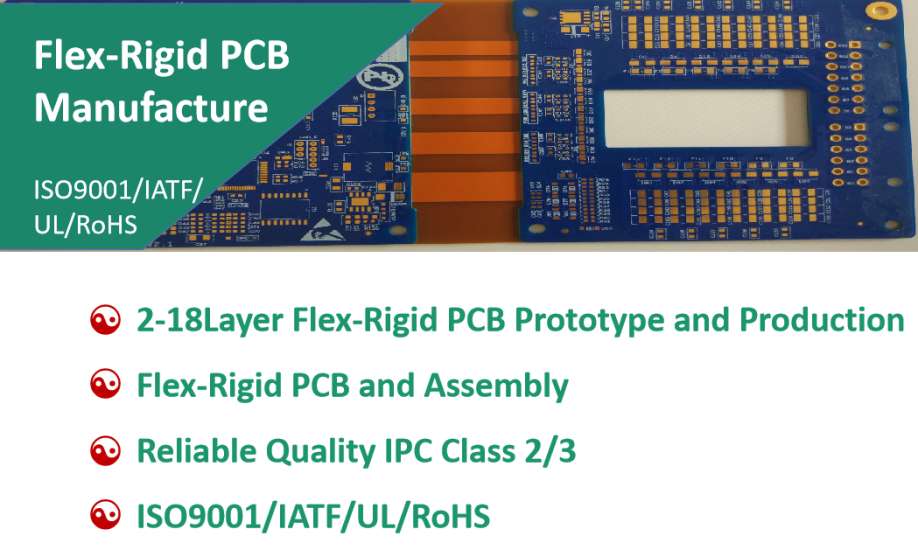

Rigid-Flex PCB

Rigid-flex PCBs are printed circuit boards highlighted by both rigid and flexible areas that make them ideally suited for a wide range of applications. The typical rigid-flex PCB circuit includes two or more conductive layers that comprise either flexible or rigid insulation material between each one - the outer layers may have either exposed pads or covers. Conductors are found on the rigid layers, while plated through-holes are found in both the rigid and flexible layers. FPCway is a leading rigid flex PCB manufacturer that produces high-quality rigid flex circuit boards. We offer fast turnaround and competitive pricing for rigid flex PCB prototypes and production.

The Advantages of Rigid-Flex PCB Technology

While this type of flexible circuit may be more expensive to design and produce, it does offer a number of important advantages. For instance, the reduced size makes it easier to fit more components into a smaller space. This can actually help to lower overall system costs. Additionally, because they require the need for fewer interconnects and related parts and components, these flexible circuit board can also prove to be more reliable and require less maintenance in the long run.

As with all types of flexible circuit boards, the rigid flex printed circuit boards will perform well in even the harshest environments, especially those featuring extreme heat. A rigid flex board is also easy to test, making it well-suited for prototyping.

Rigid-Flex PCB Solutions of the Highest Quality

Currently, AgePCB has served companies in industries such as medical, telecommunications and manufacturing with our superior quality rigid-flex PCB manufacturing services. We have an in-house quality control department to ensure your boards fabricated and assembled properly - we also guarantee the quality of all parts and components. Our engineers will even perform a Design for Manufacture (DFM) check at no additional charge.

Our experience and technical expertise enables us to develop custom rigid-flex circuit boards for any specific applications. Here is our full feature rigid flex PCB manufacturing capabilities:

Flex-Rigid PCB Technical Capabilities | |||

| Flex-Rigid PCB Layer | |||

| NO. | ITEM | Standard Capabilities | Special Capabilities |

| 1 | Flex-Rigid PCB Layer | 2-18L | 2-24L |

| FPC Material | |||

| 2 | Base Material | PI (12.5um, 25um, 50um, 100um), FR4 TG 130, 150, 170, 180 (0.05mm-3.2mm) | |

| 3 | Stiffeners | PI Stiffener: 12.5/25/50/75/100/125/150/200/250 (um) | |

| PET Stiffener: 0.125/0.188/0.25(mm) | |||

| FR4 Stiffener: 0.1mm-1.6mm | 2mm | ||

| SUS Stiffener: 0.1mm-0.5mm | |||

| Aluminum Stiffener: 0.1mm-0.5mm | |||

| 4 | EMI shielding film | HCF-6000G, PC800, etc. | |

| Board Size & Thickness | |||

| 5 | Biggest Board Size | 250mm*610mm | |

| 6 | Board Thickness | 0.6mm-5.0mm | |

| 7 | Thickness Tolerance | 0.6mm~1mm: ±0.1mm 1mm~5mm: ±10% | |

| Drill | |||

| 8 | Minimum Hole Size | 0.1 mm | |

| 9 | Holes Size Tolerance | ±0.03 mm | |

| 10 | Holes Posistion Tolerance | ±0.05 mm | |

| 11 | Minimum vias Pad Size | 0.3mm | |

| 12 | Minimum Annular Ring Size | 0.1mm | |

| 13 | Blind/Buried Vias | Yes | |

| Copper Tracks and Plating | |||

| 14 | Minimum Track Width/Space | 0.1mm/0.1mm | |

| 15 | Track Width Tolerance | 20% | |

| 16 | Tracks/Pads Position Tolerance | ≥0.06 mm | |

| 17 | Tracks/Pads To Board Edge | ≥0.15 mm | |

| 18 | Golden Finger Pitch Tolerance | Pitch:10~20mm : ± 0.03mm, Pitch:20~50mm : ± 0.05mm | |

| 19 | Copper Plating Thickness | 20-35um | |

| 20 | Hole Copper Thickness | 20-35um | |

| Surface Finish | |||

| 21 | ENIG | AU: 1-2u" Thickness NI: 40-120u" Thickness | 3u” Thickness |

| 22 | Electrolytic Nickel Gold (Hard Gold Plating) | AU: 1-50u” Thickness NI: 80-320u" Thickness | |

| 23 | Immersion Silver | Ag: 6-12u" Thickness | |

| 24 | OSP | 8-16u" Thickness | |

| 25 | Immersion Tin | SN: 10-60u" Thickness | |

| 26 | Tin Plating | SN: 5-30um Thickness | |

| 27 | ENEPIG | Au:1-4u" Thickness NI: 120-200u" Thickness Pd:1-6u" Thickness | |

| Coverlay | |||

| 28 | Coverlay Opening Size Tolerance | ±0.1 mm | ±0.03 mm |

| 29 | Minimum Drilling Size on Coverlay Opening | 0.45mm | 0.2mm |

| 30 | Minimum Square Size on Coverlay Opening | 0.7mm*0.7mm | 0.2mm*0.2mm |

| 31 | Coverlay Opening Position Tolerance | ±0.1 mm | ±0.03 mm |

| 32 | Coverlay Align Tolerance | ±0.1 mm | ±0.02 mm |

| 33 | Excessive Glue | ≤0.15 mm | |

| 34 | Minimum Area of Excessive Glue | ≤20% Pads Area | |

| Solder Mask and Silkscreen | |||

| 35 | Solder Mask Thickness | 15um +/-5um | |

| 36 | Solder Mask Tolerance For Opening Size | +/-0.05mm | +/-0.02mm |

| 37 | Solder Mask Tolerance For Opening Position | 0.1mm | +/-0.02mm |

| 38 | Minimum Silkscreen line width | 0.13mm | |

| 39 | Minimum Silkscreen Gap | 0.2mm | |

| 40 | Minimum Silkscreen Position Tolerance | +/-0.3mm | |

| 41 | Minimum Silkscreen height | 0.8mm | |

| 42 | Minimum Solder Mask Bridge | 0.13mm | |

| Board Outline & Stiffeners | |||

| 43 | Board Outline Tolerance with Steel Die | ±0.1 mm | ±0.03mm |

| 44 | Board Outline Tolerance with Knife Die | ±0.2 mm | |

| 45 | Minimum Gap Between Drilling and Board Edge | ≥0.5 mm | |

| 46 | PSA Position Tolerance | ±0.2 mm | |

| 47 | Stiffeners Position Tolerance | ±0.2 mm | |

| FPC E-Test | |||

| 48 | Test Voltage | 10-50V | |

| 49 | Insulation Test Impedance | ≥10MΩ | |

| 50 | Conduction Test Impedance | ≤50Ω | |

| 51 | Impedance Tolerance | 10% | |

| FPC Physical Property | |||

| 52 | Solderability Test | 245±5℃, 3 Seconds For One Time, Soldering Area≥95% | |

| 53 | Thermal Shock Test | 288±5℃, 10 Seconds Per 3 Times, No Delamination and No Bubbles | |

| 54 | FCCL Peel Strength | ≥0.8kgf/㎠ (1cm width sample) | |

| 55 | Coverlay Peel Strength | ≥0.8kgf/㎠ (1cm width sample) | |

| 56 | Stiffeners Peel Strength | 0.15 N/mm (Hot-Press Adhesive) 0.49 N/mm (PSA Adhesive) | |